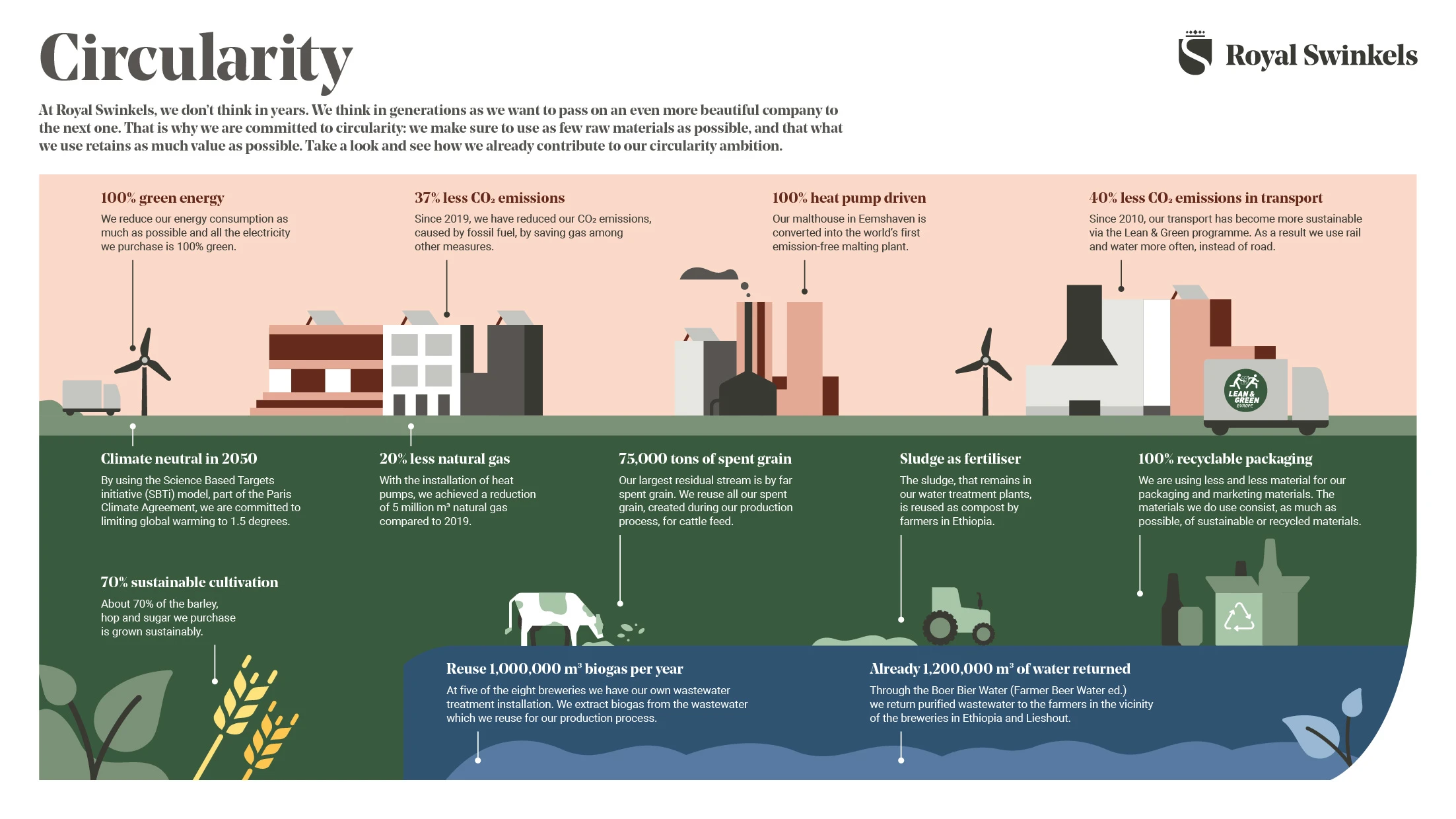

Infographic Circularity initiatives

As a family business, we don't think in years, but in generations. We understand better than anyone how important it is to pass on a more beautiful company and contribute to a greener world. That's why we focus on circular entrepreneurship: ensuring that we use as few raw materials as possible and that what we use retains as much value as possible.

Because we know that circularity is a difficult concept to grasp - and challenging to explain - we have created an infographic. Through the examples in the infographic, we aim to provide a practical insight into what we are already doing:

Explanation of the above infographic:

Top part

- 37% less CO2-emissions: Achieved by utilizing heat pumps, optimizing energy consumption, and employing a hot water buffer.

- 100% heat pump driven: As of March 2024, Holland Malt in Eemshaven is the first malthouse in the world to operate fully emission-free. Fully emission-free means there will no longer be CO2-emissions but also, for example, no nitrogen-emissions.

- 40% less emissions in transport: Achieved by shifting transportation to rail and water instead of road transport. Efficiency in routing, such as direct deliveries to customers, and maximizing truck capacity with filled pallets, also contribute.

Middle part

- Climate neutral in 2050: Since 2019, we use the Swinkels Circularity Index (SCI) to measure our circularity. But we take our responsibility a step further: that is why we are committed to the Science Based Targets initiative (SBTi) since 2022. Based on our commitment we aim to be fully climate neutral - net zero - in 2050.

- 20% natural gas reduction: Achieved through the implementation of a hot water buffer and heat pump usage. 20% is the equivalent to the annual gas consumption of 2,500 households.

- 75,000 tons of spent grain: Rich in plant proteins and fibres, spent grain is a valuable ingredient. It is also very sustainable, because we reuse the barley to produce 3 products: beer, vegetable drinks and flour. As we make these drinks and flour from a raw material already pre-processed to produce beer, we do not need extra land and water to grow the materials.

- Sludge as fertilizer: The brewing and malting process generates a special category of residual flows, named co-products. Good examples are the spent grains that remain after the brewing process, and the sludge from our waste treatment plants. We reuse these co-products and want to maximize their value as much value as possible.

- 100% recyclable packaging: All packaging is now 100% recyclable, with the goal of making all packaging 100% recyclable and composed of 100% sustainable material by 2025. Over the past years we have realized savings through thinner cans/lids, replacing shrink foil by paper packaging, using thinner or less carton, and removing foil on top of our pallets.

Bottom part

- 70% sustainable cultivation: Achieved through Sustainable Agriculture Initiative (SAI) certification. SAI is one of the most important global initiatives for sustainable agriculture. In order to keep increasing this percentage, we are constantly making arrangements with our suppliers.

- Reuse 1,000,000 m3 biogas per year: At 5 of the 8 breweries, we have our own water treatment installation. In the other 3 - Roeselare, Uiltje and De Molen - the water is also purified, yet by the government.

- Already 1,200,000 m3 of water returned: Boer Bier Water (Farmer Beer Water) is a collaboration between local farmers, the Bavaria brewery, ZLTO, the municipality of Laarbeek, the Aa & Maas water board, Agrifirm and the local Rabobank. In 2023 we returned 1.2 million m3 of clean wastewater to the ground (2021: 800,000 m3 and 2019: 400,000 m3).

All explanations and details about our initiatives cannot fit into one infographic. If you have questions or would like more information on a specific topic, please feel free to contact us.