Circular

entrepreneurship

As a family business, we feel it is our duty to ensure that countless generations after us can enjoy everything we brew and build. We want to do business in a fully circular way, because we believe this is how we can make the most impact. Circular business means not letting raw materials, energy and materials go to waste and ensuring they retain their value.

The Swinkels Circularity Index

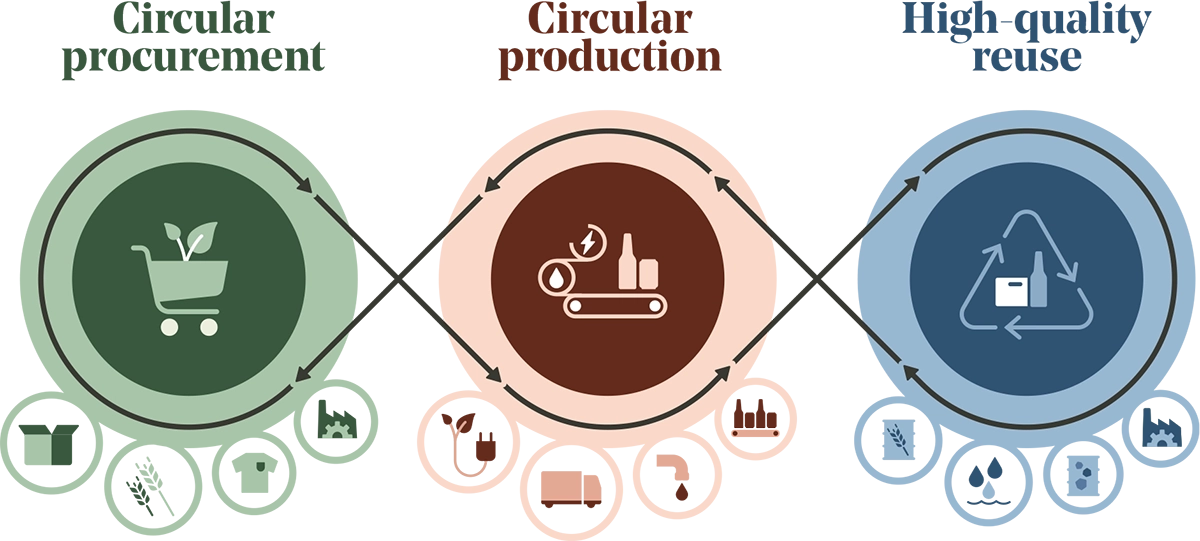

In the context of fully circular entrepreneurship, we have developed an integral method and calculation: the Swinkels Circularity Index (SCI). This method has three core processes as control mechanisms: circular procurement, circular production and high-quality reuse. The calculation method links the circularity of the entire company to concrete sustainability objectives. The Swinkels Circularity Index is checked each year by an external auditor, and forms part of the CSR information in our annual report.

The Swinkels Circularity Index guides in our daily operations and gives us the confidence to strike the right balance between our circularity agenda and business opportunities in the future.

The three areas of our business where we can make the biggest impact in terms of circularity are shown below. These form the basis of our circular entrepreneurship goals.

Circularity projects

Work in progress: ongoing projects

Infographic Circularity initiatives

As a family business, we don't think in years, but in generations. We understand better than anyone how important it is to pass on a more beautiful company and contribute to a greener world. That's why we focus on circular entrepreneurship: ensuring that we use as few raw materials as possible and that what we use retains as much value as possible.

Holland Malt opens world's first emission-free malthouse

Holland Malt, one of Royal Swinkels' operating companies, officially opened the world's first emission-free malthouse on March 14, 2024. With this step, the Eemshaven-based malthouse goes completely off gas. CEO Jos Jennissen and Groningen's Deputy for Climate, Energy, Water & Mobility, Johan Hamster, personally turned the handle, making the emission-free malthouse a reality. By completely turning off the gas tap, Holland Malt changes its gas consumption of 18 million m³ and about 33,000 tons CO₂ emissions to absolutely zero.